Infrared Thermal Imaging

"A predictable maintenance"

How will Thermography benefit your facility or home?

1. It will eliminate unexpected shutdowns for critical equipment.

2. Safety for all occupants will be increased.

3. The efficiency of critical equipment will be increased.

4. Prevent costly repairs through early detection.

5. Helpful to ensure that new, altered, or equipment still under warranty is functioning properly.

6. Detect unforeseen damage during home inspections.

7. Will give homeowners a piece of mind that their home is electrically free of hazards.

How often should this service be performed?

According to NFPA 70B Section 2 (11.17.5 ) States “Routine infrared inspections of energized electrical systems should be performed annually prior to shut down. More frequent infrared inspections, for example, quarterly or semiannually, should be performed where warranted by loss experience, installation of new electrical equipment, or changes in environmental, operational, or load condition.

Your equipment is categorized based on its “Criticality to Operation” (CTO).

The three CTO operations are:

1.Critical to operation “C”

2.Essential to operation “E”

3. Non-Essential to operation “N-E”

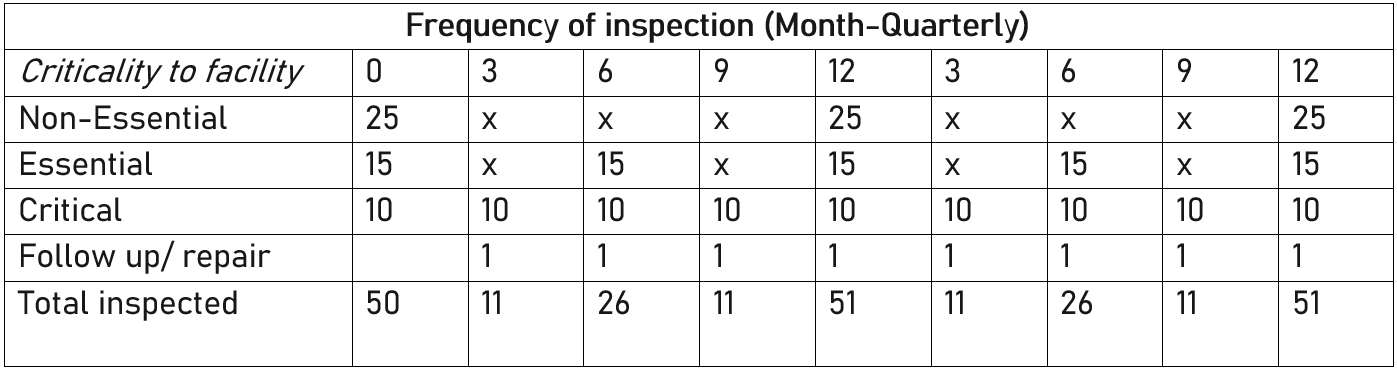

If we create a timeline for your facility’s equipment, it is recommended that the specific piece of equipment be serviced at these intervals.

1.Critical equipment every 3 months

2.Essential equipment every 6 months

3. Non-essential equipment every year

For example, here are a few random quantities to represent your facility’s equipment and how they will be organized to form a quarterly schedule for inspections.

1.Critical to operation= 10

2.Essential to operation=15

3. Non-Essential to operation=25

4.Followup/repair=1

Why choose IES to take care of your Thermal imaging needs?

Being a customer of ours we will deliver detailed quality reports of your valuable equipment that can be trended overtime. Trending will help monitor pieces of equipment over periods of time to track a potential anomaly before its critical state occurs. Thankfully Integrated Electrical can troubleshoot and repair anomalies that can put your equipment at risk of failure.

Some thermal imaging companies do not employ electricians at all. They simply subcontract out their findings to a third party resulting in much higher prices for the customer and a lower priority for your equipment due to the scheduling between parties. Integrated can ensure you if a critical anomaly is found we will give the highest priority to protecting your equipment from potential damage in the safest manner possible.

OUR LOCATION

HOURS

HOURS

CONTACT US

csidoti@integratedelectric.com

csidotijr@integratedelectric.com